- 11/09/2024

- 10 Min Read

- By: Christian Schaefer

Deserts, and Streams, and Highways? Oh Yeah! - FCP Euro's Rallye Cayman Project Is Built To Tackle It All

Porsche is unmistakably known for their successes in endurance racing, but the company has taken on motorsports of all kinds, including stage rallies. From three consecutive overall wins at the Monte Carlo Rally in the late sixties to the iconic images of the 953 and 959 on their way to their respective victories in the Paris-Dakar Rally in the eighties, many of Porsche’s older sports cars are undoubtedly linked to loose surface competition. In recent years, that history has been brought into the spotlight with the “Safari” movement, as enthusiasts have taken their 911s, 924s, and 944s and jacked them up on big tires and raised suspension to experience how Porsche’s engineering translates to off-road use.

Even Porsche has gotten in on the movement, debuting the first 992 Dakar as the first mass-produced, off-road-prepped 911. But the average safari Porsche build is only like those past champions in spirit. They may have oversized, knobbly tires and lifted suspension, but they’re almost all just a few parts away from their original spec as a road car as not much more than nearly $100,000 toys for the relatively wealthy to play rally driver in. Their off-road ability is improved, but they don’t carry the complete Porsche engineering that has made many of its sports cars dominant in other spaces.

FCP Euro’s Nate Vincent is quite familiar with Porsche engineering, especially regarding stage rallies, as one of his first jobs in college was disassembling and documenting a 911 SCRS campaigned by ProDrive in Group B. While he’s the BMW Product Director, his love for competitive rallying and the constant bombardment of lifted Porsche “builds” on social media pushed him to plan FCP Euro’s next big build, a modern Porsche built for the American Rally Association’s Open 2WD class. In his own words, “It was about taking the potential that these cars [Porsches] have with the trendiness of Safari 911s and a more humble approach with the Cayman and putting that forward, saying basically, ‘hey you don’t need an $80,000 air-cooled 911. You can just pick up an old Cayman that’s not worth all that much money.’”

It didn’t take long for the project to be approved, and after the Golden Era 190E project’s success, Hengst quickly signed on as the primary sponsor. Within weeks, a 2008 Cayman S in Seal Grey sat in the FCP Euro parking lot, awaiting the unique conversion into a modern rally machine. However, before any cutting, measuring, or 3D scanning could occur, Nate and the car took a quick trip North to the Team O’Neil Rally School.

In the snow-covered forests of Dalton, New Hampshire, the Cayman was put through its paces on the rally stage testing grounds where names like Ken Block and Travis Pastrana cut their teeth in their early days of stage rally.

Even at its low ride height, the Cayman cut through the snow, with its mid-engined balance playing well over the elevation changes and slick surfaces of the school’s slalom and skidpad. However, some time on a lift with Team O’Neil’s Wyatt Knox highlighted more than a couple of areas where the Cayman would need reengineering to meet the vastly different requirements of rally stages rather than the tarmac surfaces it was designed for by Porsche. But that was expected, and the initial performance provided by the unmodified Cayman was enough to be excited about.

“I think it was a little bit ride height limited,” Nate shared of that first test day, “But as far as drivability, comfort, and control, the car was really good. The big takeaway was that the ABS system worked really well, even on the slippery stuff, and allowed you to get good control and feel of the car while also slowing it down.” Complex electronics like those of modern ABS systems can present a considerable challenge when converting a car from road use to a competition-based format. However, the ABS system’s cooperation allowed the project to move on to reinforcing the chassis and gaining suspension travel.

Immediately following the trip to New Hampshire, the Cayman returned to FCP Euro HQ, where Nate stripped the interior as far as it could go before being sent off to Bill Doyle at CageThis for its FIA-spec roll cage. Along with providing enough safety to protect the driver and co-driver, the cage also serves as a stiffening agent for the chassis. Tying in the strut mounts prevents any deformation in the chassis that a long jump at well over 60mph could cause and allows the specialized dampers to absorb those hits effectively. Yet, while the cage was coming together at CageThis, the project gained its most significant development, Automotive Design Engineer Alex Nelson.

Hired at FCP Euro after the project had already started, his previous talents supporting Porsche Motorsport and designing intake and exhaust systems for MAPerformance were immediately put to use after he realized the gravity of the project. “So, the first time I saw it was picking it up from getting caged, and the first thing I thought of was the difficulty,” Alex said. “It wasn’t just ‘What parts are going to bolt on?’ We have to fundamentally change what the vehicle is.”

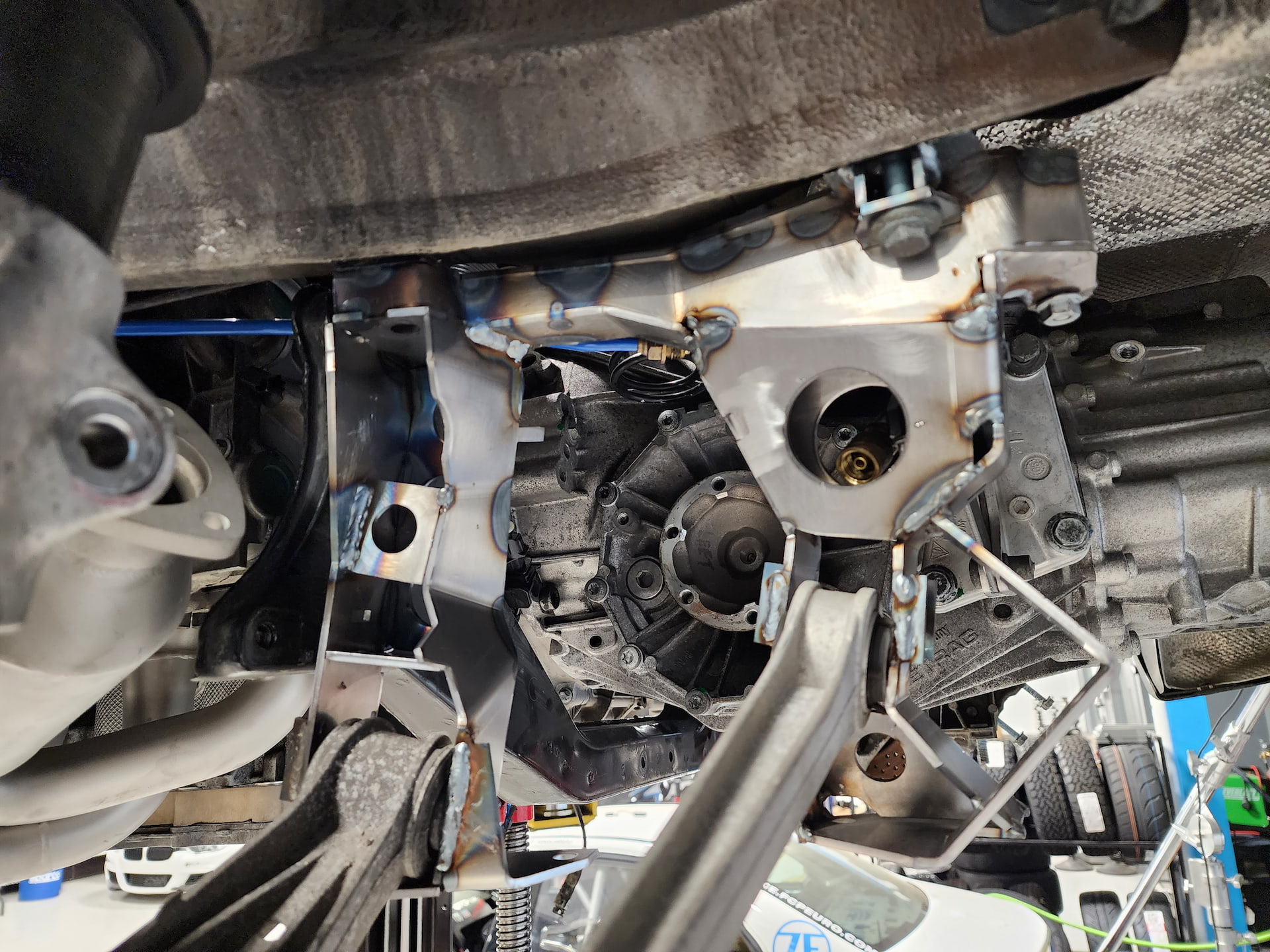

Having previous experience working on newer Cayman generations, Alex was already acutely aware of the challenges Nate and Wyatt discussed at Team O’Neil. “The aluminum rear subframe cradles couldn’t handle off-road use, the front chassis couldn’t handle off-road use, and the cooling system is right in the way of everything.” Each of those areas was going to need considerable reengineering to survive sliding through the forest at highway speeds, so while Nate began on the suspension, Alex turned to the cooling system.

All modern Porsche sports cars—whether the Boxster, Cayman, or Carrera—have at least two radiators, each tucked in front of the front wheels. “I actually can’t think of a worse place to have radiators on a vehicle that’s going off-road,” Alex explained, “Any rocks that touch the tire are going to also hit the radiator at some point. So, we had to move every part of the cooling system just to keep it safe.” That last line is a bit of an understatement, as the entire front half of the cooling system wasn’t so much as moved but redesigned into a more compact package in the trunk while retaining almost all of the OE components.

.jpg)

Alex’s 3D trunk scans showed plenty of room for the OE-size radiators in a V-mount setup. An aluminum plate was cut and bent into shape to provide a frame for radiator mounting and rubber isolators were fitted to absorb hard hits to the front end that may affect the cooling system. Another custom aluminum frame was cut and secured over the aluminum radiators provided by CSF to hold the OE fans. Inspired by the then-recently released 992 GT3RS, Alex carefully measured and cut two holes in the hood before 3D printing hot air ducts to vent the hot radiator air out through the hood.

The revised radiator packaging has worked flawlessly for the thousands of miles the Cayman has driven since its completion. It’s traversed washboard fire roads in the Pacific Northwest, Arizona’s sandy desert terrain, and the Sierra Nevadas’ mixed conditions in Utah without a single hiccup. Only once has the temperature gauge climbed above normal, but a little more coolant in the system quickly solved that issue.

The chassis reengineering has worked similarly well on all of those adventures, which, while not surprising, is one of the biggest positives of the entire project.

Finding grip on loose surfaces is always challenging, but decades of serious competition have shown that the right tire and suspension setup goes a long way. In its stock form, the Cayman could have been better in that environment, as Nate experienced in that first test. “I mentioned it in the episode a little bit,” he explained, “ but it tended to bias towards floaty understeer. The car was just set up for stiffer, more grippy environments than we had it, so we had to let the chassis move around a little bit more.”

Weight transfer is crucial to the dynamics needed to get a car to rotate as wanted on gravel or snow, and the low and stiff OE springs and dampers on the Cayman would not cut it. The car needed a softer suspension with significantly more travel, but it couldn’t be from a set of ultra-modern WRC-esque dampers. The emphasis on the build also being achievable by anyone with the skills to weld and measure meant sticking to a tighter budget.

“I knew that the big Bilstein dampers existed on the market,” Nate said. “They were very hard to find, but I knew they were out there and were DIYable.” The dampers he’s referring to and the ones on the car today are an older 50mm Bilstein coilover unit you’d find in the analog days, and while it might sound like some kind of a downgrade, it was anything but. When fitted, the Cayman jumped from four inches of front suspension travel to ten inches of travel, with softer spring rates to let the car dive and squat. “With that change, we could run lower spring rates on the front and let the front dive more to really get that weight transfer.”

But the dampers were only half of the equation for getting the grip of a competitive rally car in the Open 2WD class for would need. The rest was going to come from the tires.

“I wanted someone with expertise to be able to look at the car and be like, ‘okay, yeah, they covered their bases,’ and if you want to do proper rally tires, you have to have 15-inch wheels,” Nate explained. Pirelli’s K series rally tires are the go-to for almost everyone competing on loose surface rallies. They’ve been engineered over decades and have provided the grip for many championship-winning machines; they’re only available for fifteen-inch wheels. But the Cayman wasn’t designed for a wheel smaller than seventeen inches. Shrinking the brake diameter was easy, requiring a swap to the non-S Cayman brake package. However, that didn’t solve the rear suspension knuckle.

The rear toe link mounting point on a rear 987 knuckle sticks out from the wheel centerline enough to significantly impede a fifteen-inch wheel. Making the wheel fit would require redesigning most of the rear suspension or highly custom parts. “We were planning to make bespoke uprights to connect all the rear suspension together. I had reached out to Bipar in Australia and Rennscot in Massachusetts. They have a full engineering facility and CNC machines, so we were getting into a $10,000 CNCed upright,” Nate said.

But that never materialized as Nate had an idea never before put into practice. “As I was doing a lot of the engineering around the front suspension, I kind of looked at it, and I’m like, the front and the rear are almost identical. I was literally in the shower one morning. I go, ‘I wonder if we can take a right front and put it on the left rear and a left front and put it on the right rear and see what happens.' When we got to the shop, Alex scanned and overlaid both knuckles. We were like, ‘holy crap, the entire geometry is exactly the same except for the toe link from the center line.’”

At that moment, Nate and Alex no longer needed custom suspension components worth half the donor car. Instead, it’d be about $150 in used knuckles and whatever a fresh set of wheel bearings cost at the time. However, while that cut significant costs, it didn’t solve the issue. A custom toe link would connect the subframe to the knuckle but completely throw the rear suspension geometry out of whack, rendering the knuckle solution pointless.

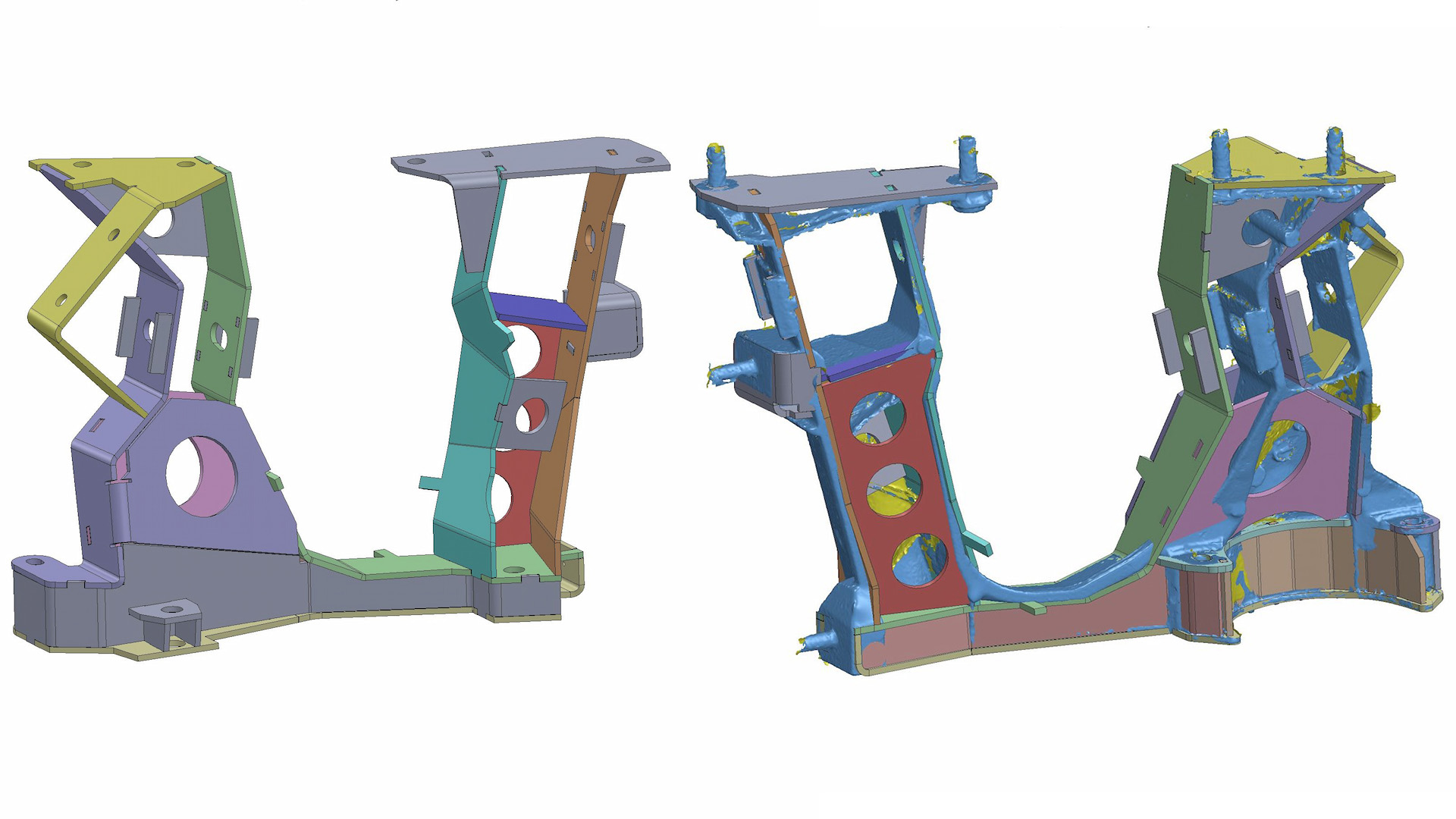

The answer was a reengineered subframe, strengthened to withstand rally abuse and modified to move the toe link’s mounting point further forward. The strengthing was necessary as the Cayman’s aluminum rear subframes are known weak points within the rear suspension, even though they carry the engine, gearbox, and rear suspension pickup points. So messing with the inner toe link pickup points should’ve been easy, right?

“I want to say it was 42 individual parts between both sides that I had to weld together. It’s probably the most complex sheet metal part I’ve ever made, and it was made in a week,” Alex shared. “We fully redesigned the rear subframes, which are cast aluminum, and we know we’re gonna have to beef them up, but we ended up completely redesigning them to be made out of eighth-inch steel.”

Automakers spend thousands of hours designing and miles testing suspension, with many revisions, but Alex did it in one shot without causing any lasting issues plaguing the car after completion. Within two months of joining the company, Alex used his engineering skills to prepare the Cayman for its first public unveiling at a Sunday Motoring Meet as a rolling concept with its redesigned suspension and repackaged cooling system.

Between all of the suspension and cooling system work, some time was spent prepping the Getrag gearbox and M97.21 engine for motorsport abuse. After the cage went in, Nate and Alex pulled the engine and gearbox to refresh them and bolt on a few standard upgrades, including Soul Performance headers and exhaust system, an aluminum single-mass Aasco flywheel, a Sachs Performance clutch, a GT3RS shifter assembly, and an OS Giken limited-slip differential. It was all pretty standard work, that is until it came to the intake.

Caymans and Boxsters use the openings in their quarter panels for their intake air, which presents a problem in a rally car. “The goal for the intake was to keep dirt and dust out of the intake because the factory ones are on the side of the car, which doesn’t work at all when you’re sideways; everything kicks up,” Alex shared. With the engine in the middle of the car, the intake couldn’t be angled down toward the ground, forward to the cabin, or rearward to the trunk, so Alex sent it upward.

“I wanted to figure out how to represent Hengst and what they do. I thought, ‘What better way to show what Hengst does than to literally show the filter doing his job?’” With the engine sitting directly below the rear window, which would be replaced with plastic anyway, Alex and Nate developed a defining feature and a perfect way to feature the main sponsor’s expertise. “We took an IPD plenum, rotated it 90° upward, and paired it with a GT3 throttle body. From there, we made a 3D-printed metal air box for the filter, which is also the MAF sensor housing. It’s a high-dust Cayenne air filter with a foam layer on top,” Alex shared. “The top airbox is clear, so you can see the dirt accumulating on the filter as it does its job, and then it runs up into a gasket that is sealed on the rear hatchback.”

If you ever see the car, you’ll notice there isn’t a bulkhead between the driver’s compartment and trunk, where the air filter and throttle body come up and out through the carbon roof scoop. It makes for a very loud experience, but one that unfailingly leaves its occupants with an unshakeable smile upon exiting the car. There are a few reasons for that, but the air intake just inches behind the passenger’s head delivers a constant wailing symphony of flat-6 music that inspires the driver to stand on the loud pedal as much as possible while captivating those who’ve had the chance to see it sliding around in its natural habitat.

All of that hard work and clever engineering came together over just seven months, as the ultimate goal was to make it to the SEMA and AAPEX show in Las Vegas, where auto parts manufacturers team up with builders to create wild and exciting vehicles to show off new technologies. Many of those builds are simply assembled for the show and rolled in as pieces to look at rather than functioning concepts, but that wasn’t with the spirit of the car and the project. So, before heading to Vegas, the Cayman arrived—freshly wrapped by Rabid Wraps in a blue and yellow Hengst livery—in Oregon with Nate and Alex for a shakedown adventure on an Overcrest Rally.

After grabbing the Cayman from its cross-country transport, the pair of engineers arrived at the start point of the rally, standing out amongst a sea of primarily vintage and European cars, enormous 3D printed light pod, and all. While the old Alfas, BMWs, and Porsches were fine on the rally, the Cayman was in its element, tackling the conditions it was built for. "When we were going down those fire roads, it was just the car floating around; it was awesome. The gravel was smooth. The tires were amazing," Nate said. "That was my first time on proper Pirelli gravel tires, and they just took so much abuse and just had so much grip. It was actually a lot of fun, playing with brake bias, letting the car lock up, going into the corner, and stuff like that. It was great."

Since then, the Cayman has performed as well as it did on that first rally. It made the trip from the Mesa, Arizona, distribution center to Los Angeles and stopped off along the way for some fun in the sand. At Air/Water, it captured the imagination and enthusiasm of thousands of Porsche fans as a fully functioning display of the passion FCP Euro employees bring to their work every day. It even made the incredibly treacherous drive into Manhattan for Attack of The Racks. Soon after that event, it received a livery change, but the rest of the car has remained its incredibly capable self, most recently taking on the Safari Party Rallye in the Utah desert with the "safari builds" it was designed in spite of.

What does the future hold for the Cayman? Nate and Alex have different ideas. Nate, the slightly more pragmatic of the two, said, "I would love to change the ring gear to a 4.40. A close-ratio gearbox would just be killer on that thing. The other thing planned to be finished and never was just because we ran out of time was power steering. Obviously, with the weight in the back, it's not the end of the world, but anything off-road where you're hitting rocks and stuff that hurts. You feel it through your hands."

"The Cayman's front hubs are splined like the rears, so you could make a four-wheel drive Cayman," Alex said. That would be a very fun future development, although I'd probably lose the rest of my hair. You can quote me on that."

Cayman S Rallye Specifications

EXTERIOR:

Livery design by Yago Design/Blackfish Graphics

Livery install by Rabid Wraps

Rear wing by Pepper Play Works

Front arches by Vali Motorsports

Custom light pod

Custom front bumper ducts and hood vents

ENGINE:

Standard M97 engine/drivetrain

FCP Euro Motorsport engine top airbox with roof scoops with Hengst filtration

Soul Performance headers & exhaust with catalyst

Re-engineered cooling system

Relocated under hood

Dual coolers

Custom front-bumper ducting

Custom hood venting

TRANSMISSION:

OS Giken LSD

FCP Euro differential install kit

997 GT3RS shifter

Function First shifter cable modifications

BODY:

Reinforced chassis

FIA rally spec roll cage by CageThis

Painted interior, trunk, and front trunk

FCP Euro Motorsport FIA spec seat mounts to achieve the lowest seat height

SPARCO “Circuit” driver and passenger seat

SPARCO 6-point harnesses

Custom spare tire mount with SPARCO hold-down

Custom front skid plate & engine sump guard

SUSPENSION:

Bilstein custom 50mm gravel dampers

Custom-machined front uprights for all four corners

Custom steel rear subframes with toe link correction

Custom billet 6061 top mounts

BRAKES:

Base 987.1 Cayman brakes for 15” wheel clearance

Dual AP master cylinders

CompBrake balance bar and booster delete

Nameless Performance hydraulic hand brake in series

WHEELS/TIRES:

Braid 15x7 ET15 Acropolis gravel wheels

Pirelli WRC hard compound tires